Product Categories

All Products

-

Hose adapter

The steak Saver allows you to screw a standard, 1 lb. propane cylinder onto your gas grill, and with no time lost you're ready to continue grilling. It also lets you hook up your gas grill to the gas system on your RV in case you have an unexpected outage. These are the same one-pound tanks that are available in all stores and home center. In fact, you may even have one or two of these tanks in your home garage as part of your soldering torch kit. Then, the following day, you can bring your tank in to have it refilled, when it is convenient for you - not when you have to.

-

Pipe adapter fitting

An adapter is an interface converter that can be a standalone hardware interface that allows hardware or electronic interfaces to be connected to other hardware or electronic interfaces, or to information interfaces. For example: power adapter, tripod base adapter parts, USB and serial port switching equipment.

-

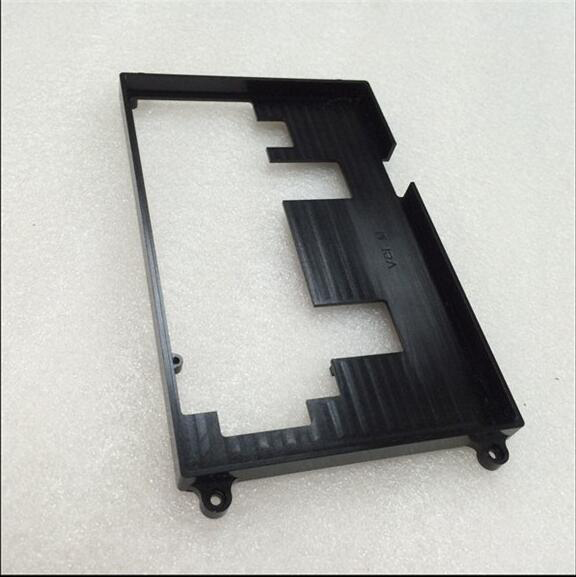

CNC machining

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Cast alumium parts

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Brass casting

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Metal sheet

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Stamping parts

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Fireplace gas valve

Gas valve is a new type of gas pipeline project safety equipment; used to cut off, connected, adjust the pipeline in the gas, has good control characteristics and closed sealing performance; for urban gas, liquefied petroleum gas, natural gas, Oxygen and other gas medium pipeline.

-

CE approved gas cooking oven valve

Gas valve is widely used in city gas supply network system gas, liquefied petroleum gas, natural gas, oxygen and other gas medium pipeline. Drive in the form of manual, worm gear, electric, pneumatic, hydraulic, electro-hydraulic linkage and other implementing agencies, remote control and automation can be achieved.

-

High qualtiy gas valves brass valve

Gas valve is a new type of gas pipeline project safety equipment; used to cut off, connected, adjust the pipeline in the gas, has good control characteristics and closed sealing performance; for urban gas, liquefied petroleum gas, natural gas, Oxygen and other gas medium pipeline.